Concrete screw with mushroom head FBS II Fischer

Strong and easy-to-install concrete screw.

Advantages

The first concrete screw with a diameter of 6 mm and variable anchorage depth enables universal use and adjustment of the screw to the load level.

The ETA Technical Assessment (Option 1) allows the screws to be used as single fixing points in cracked and non-cracked concrete.

The European Technical Assessment ETA allows for anchoring in seismic zone C1, which is an additional safety confirmation.

The UltraCut FBS II 6 screw is also suitable for multiple fixings in non-load-bearing systems and is therefore ideal for the installation of pipelines, cable routes to prestressed concrete ceilings.

The holes do not need to be cleaned during vertical installation (ceiling and floor). For floor fixings, the hole should be drilled 3 times deeper than the hole diameter.

Different head types ensure universal use and a perfect fit.

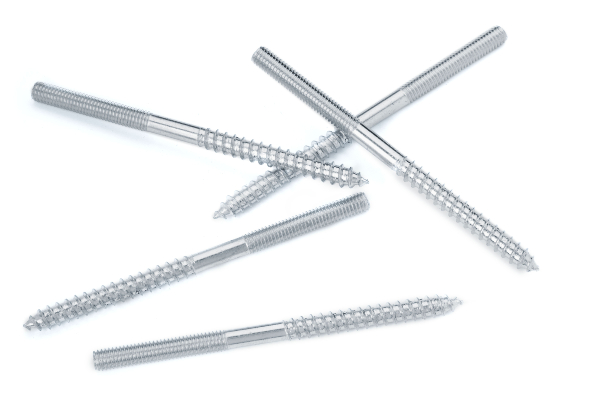

The screw version with internal stepped thread is very useful for mounting threaded rods or connectors.

According to the Technical Assessment, the screw can be adjusted by unscrewing it twice and placing a washer with a maximum thickness of 10 mm and screwing it back in.

The UltraCut FBS II 6 concrete screw is suitable for use in masonry (i.e. in solid building materials).

The FBS II 6-10 concrete screw is available in galvanized, CP coated steel and R stainless steel versions, and the ETA Technical Assessment allows it to be used in masonry (including plastered) made of bricks (EN771-1), silicate blocks (EN771-2) and silicate blocks with holes (EN771-2).

The UltraCut FBS II 6 P concrete screw is made of galvanized steel with a large mushroom head. The UltraCut FBS II 6 LP is ideal for securing pipelines, cable routes, ventilation ducts and other building equipment. When the screw is screwed into the hole using a tangential impact drill, it cuts into the concrete and creates a strong, form-fitting attachment. The low effort required for installation allows for quick installation when serial fastening is required. The European Technical Assessment permits the screw to be used in cracked or non-cracked concrete and for installation in seismic zones, while the documented fire resistance of R 120 ensures safe operation.

Product inquiry form

- Group

- 5690