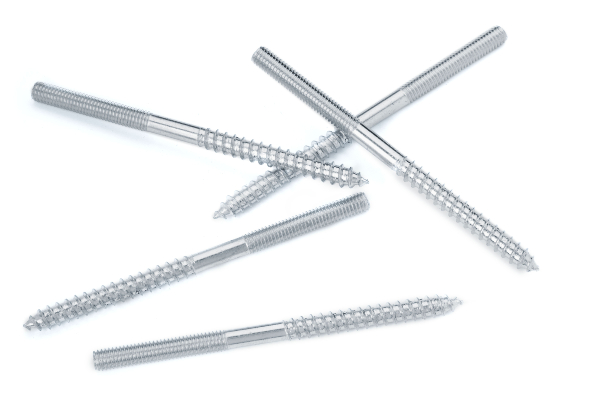

CS451X abrasive sleeve

Klingspor CS 451 X abrasive sleeve – high durability and so-called cold grinding

The CS 451 X abrasive sleeve manufactured by Klingspor is characterized by high durability and ensures a reduction in grinding temperature. It is designed for the processing of high-alloy stainless steel and aluminum and has many advantages:

stable canvas

high aggressiveness

cooling multi layer

precise work

The Klingspor CS 451 X abrasive sleeve is easy to use and is great for grinding welds and edges.

CS 451 X abrasive sleeve – aggressive grinding and precise work

The CS 451 X sleeve has a canvas substrate made of X-cotton, which is characterized by particularly high tear strength and stability. The cotton substrate with high tear strength is additionally reinforced on the inside to provide special stability. The abrasive material is a full coating of zirconium electrocorundum bonded to a synthetic resin substrate. The abrasive material is hard, durable and has self-sharpening properties. It is characterized by slow wear and long service life. The abrasive sleeve offers high efficiency and aggressiveness. A consistently good surface quality is ensured during grinding.

CS 451 X abrasive sleeve for precise applications

The CS 451 X abrasive sleeve is designed for precise applications and enables, for example, efficient work with an angle grinder. The abrasive sleeve has a cylindrical shape and is spirally bonded. It can be used on the GK 555 rubber shaft.

CS 451 X abrasive sleeve with multi-layer to reduce the grinding temperature

The CS 451 X sleeve has an additional multi-layer that offers special properties when grinding stainless steel. The multi-layer prevents the ground material from clogging the fill and reduces the temperatures caused by friction. In this way, the so-called "cold grinding" is achieved. The processed material adheres less to the grain peaks, which results in a significant increase in the amount of ground material. Thanks to the reduced grinding temperature, the components do not suffer from discolouration caused by high temperatures.

Product inquiry form

- Group

- 66E1