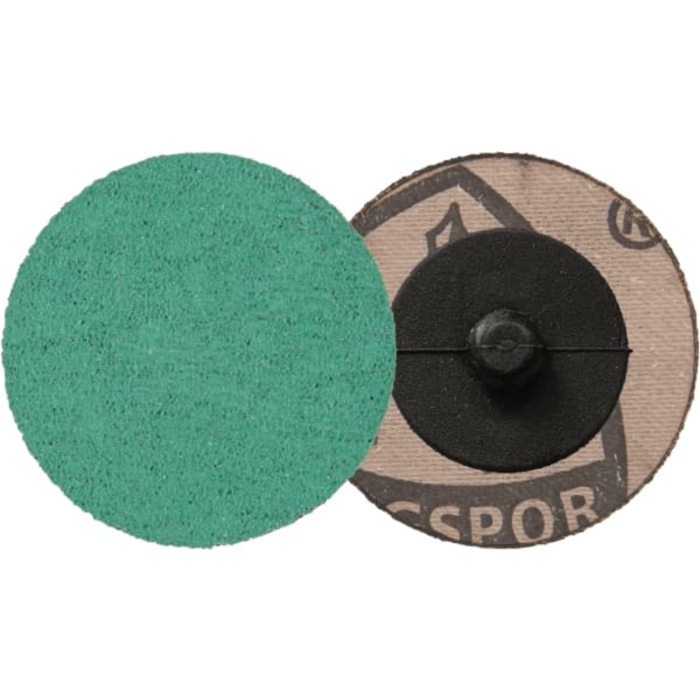

QRC 910 Mini-Disc

QRC 910 – Quick Change Disc mini discs for stainless steel and high-alloy steel

Quick Change Disc mini discs with plastic thread attachment QRC 910 mini discs are the ideal product for grinding:

stainless steel and

high-alloy steel.

The full grain coating on these mini discs ensures the highest level of aggressiveness and grinding performance as well as a long service life of the mini disc. Since Klingspor only uses synthetically produced ceramic fused corundum, the quality and size of the abrasive grains do not change. The full grain is ideal for grinding stainless steel and high-alloy steel.

Full grain of fused corundum for fast, precise grinding

Ceramic fused corundum forms irregularly shaped grains with a microcrystalline structure. The Quick Change Disc mini discs with plastic thread attachment have a full grain coating and a synthetic resin bond. The applied full coating of microcrystalline self-sharpening grain almost completely covers the disc surface. It ensures the highest aggressiveness even when grinding hard materials such as steel. Synthetic resin is a very strong and adhesive bond. Compared to natural bonds, this results in greater adhesion of the grains, which results in a better, more even grinding result and a longer service life of the mini abrasive disc.

Fast and safe grinding with Klingspor Quick Change Disc mini discs

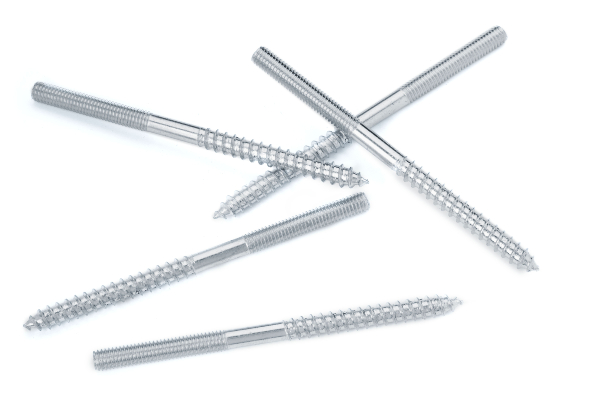

Quick Change Disc mini discs with plastic thread attachment The QRC 910 mini discs can be mounted very quickly to the support disc thanks to the plastic threaded sleeve. To attach the Quick Change mini disc to the support disc, simply turn the mini disc 180° to the right. The support disc is the ideal complement to the mini disc. The hardness of the discs determines whether the mini disc grinds with a high stock removal and high aggressiveness or is more suitable for fine grinding. Hard support discs enable more material to be removed.

Product inquiry form

- Group

- 66F6