Quality

Quality – Highest standards

From the beginning of its activity Marcopol focuses on the high quality of services and products produced. The confirmation of our efforts is the Quality Management System, implemented since 2002, in accordance with ISO 9001: 2015.

In the following years, focusing on the sustainable development of the company based on respect for the natural environment, we implemented the Environmental Management System based on the model compliant with ISO 14001: 2015.

Respecting the safety and health of our employees, we have implemented the Occupational Health and Safety Management System in accordance with ISO 45001: 2018, which goes beyond the legal requirements in the field of health and safety and is the basis for the continuous development of safe workplaces.

Currently, all these elements form an integrated quality, environment and work safety management system.

In addition, to meet the requirements of our clients and legal requirements, we maintain the FSC CoC system – Standard for Responsible Forest Management, FPC – Factory Production Control for construction products and AEO – Authorized Entrepreneur Status.

Integrated management system policy – document in preparation.

Since the beginning of 2022, our company has embarked on advanced efforts to implement the IATF 16949:2016 standard, underscoring our commitment to continuous improvement and aiming for world-class quality standards. The adoption of this prestigious automotive industry standard is testament to our determination in delivering products that meet the expectations of global customers. This strategic initiative reflects our dedication to fostering innovation and striving to be a leader in quality management within the automotive industry.

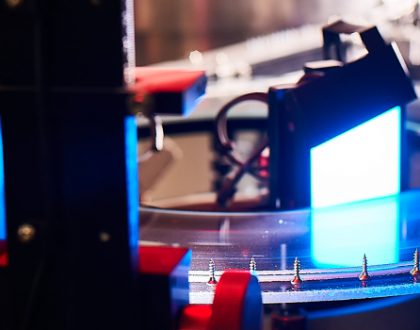

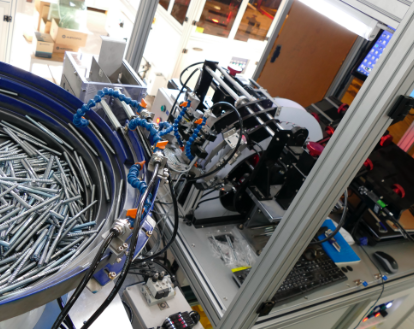

AUTOMATIC OPTICAL SORTING MACHINE – TYPE 1

Find out moreOptical sorting machines introduced in Marcopol Quality Control Department are the answer to the high requirements of our Customers. The state-of-the-art digital technology, sensitive CCD cameras and a range of rotating sorting discs of different thickness ensure the highest precision in quality control of every product. The optical sorting technology combines the recognition of, among other things: diameter, size, shape and length of the shank with the detection of coating micro-defects, or damage to the first coil of the thread and its corrugation. The automatic control process guarantees our Customers stability and quality.

INTENDED USE: Quality control and sorting of small products such as: metric screws, wood screws, sheet metal screws and bolts up to 25 mm in length and 2.5-10 mm in diameter.

SCOPE OF OPERATION: range of diameters of tested products: M 2,5 – M 10 mm, maximum length of tested products: less than 25 mm.

SCOPE OF TESTING: the following parameters can be checked: diameter/height/head shape/, shape/defect of recess, thread outline/pitch, shank perpendicularity, total length, shank length, first coil of thread, wavy thread, cracks, coating defects, thread diameter, core diameter, thread defect, insertion length/diameter.

PRODUCTIVITY: 400 pieces per minute.

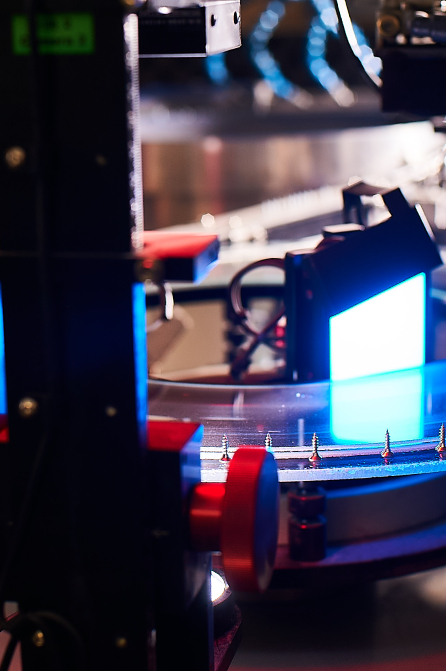

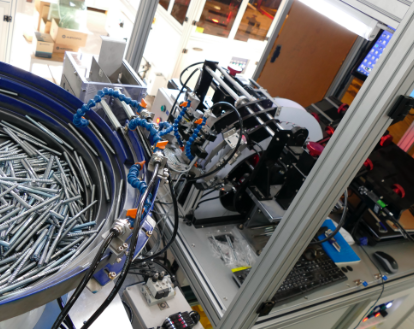

AUTOMATIC OPTICAL SORTING MACHINE – TYPE 2

Find out moreOptical sorting machines introduced in Marcopol Quality Control Department are the answer to the high requirements of our Customers. The state-of-the-art digital technology, sensitive CCD cameras and a range of rotating sorting discs of different thickness ensure the highest precision in quality control of every product. The optical sorting technology combines the recognition of, among other things: diameter, size, shape and length of the shank with the detection of coating micro-defects, or damage to the first coil of the thread and its corrugation. The automatic control process guarantees our Customers stability and quality.

INTENDED USE: for quality control and sorting of a wide range of production products with a length between 15-110 mm and a diameter between 2.5-12 mm.

SCOPE OF OPERATION: range of diameters of tested products: M2.5 – M12 mm, maximum length of tested products: 15 – 110 mm.

SCOPE OF TESTING: the following parameters can be checked: diameter/height/head shape/, shape/defect of recess, thread outline/pitch, shank perpendicularity, total length, shank length, first coil of thread, wavy thread, cracks, coating defects, thread diameter, core diameter, thread defect, insertion length/diameter.

PRODUCTIVITY: 900 pieces per minute.

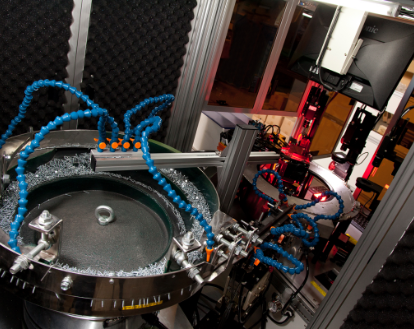

AUTOMATIC OPTICAL SORTING MACHINE – TYPE 3

Find out moreOptical sorting machines introduced in Marcopol Quality Control Department are the answer to the high requirements of our Customers. The state-of-the-art digital technology, sensitive CCD cameras and a range of rotating sorting discs of different thickness ensure the highest precision in quality control of every product. The optical sorting technology combines the recognition of, among other things: diameter, size, shape and length of the shank with the detection of coating micro-defects, or damage to the first coil of the thread and its corrugation. The automatic control process guarantees our Customers stability and quality.

INTENDED USE: for sorting and quality control of threaded products of different diameters.

SCOPE OF OPERATION: range of diameters of tested products: M4 – M10, maximum length of tested products: 70 – 150 mm.

SCOPE OF TESTING: bend, thread diameter, core diameter, wavy/defective thread, thread pitch, total length.

PRODUCTIVITY: 60 pieces per minute.

Tensile testing machine

Find out moreINTENDED USE: allows for measuring the breaking load (tensile strength) and is one of the tests confirming the class of mechanical properties. Mainly used for breaking screws, bolts and selected pins with appropriate specimen lengths (the minimum length of the specimen to be broken should be greater than twice its diameter).

TESTING RANGE: measurement range: 0-500kN, encoder accuracy: class 1 for the range 2,5 – 500 kN according to EN ISO 7500-1.

VICKERS’A FALCON HARDNESS TESTER

Find out moreThe new generation Vickers Falcon hardness tester guarantees 100% accuracy, repeatability and reliability for any load. Testing with this device eliminates the possibility of measurement error. Modern software installed in the device enables saving of files, storing of measurement results, image zoom, auto focus, conversion to other hardness scales, determination of hardness distributions (CHD, Nht, Rht o parameters) and determination of the Kc parameter. The test is destructive (the sample is destroyed). Evaluation of the product quality and safety, carried out by modern testing machines, allows for detecting any structural irregularities and areas most vulnerable to damage due to intensive use.

INTENDED USE: measures the hardened layer thickness by analysing the distribution of values. It allows measuring the hardness of products of all mechanical property classes. Examines hardened fabrication products, sheet metal screws, grade bolts and others – as needed and recommended.

TESTING RANGE: measurement possible with loads between 0.3HV and 30HV (0.3HV, 3HV, 5HV, 10HV, 30HV). Brinell range: HB1, HB2.5, HB5. Load force accuracy up to 99-99.5%.

TESTING ACCORDING TO ISO 6507

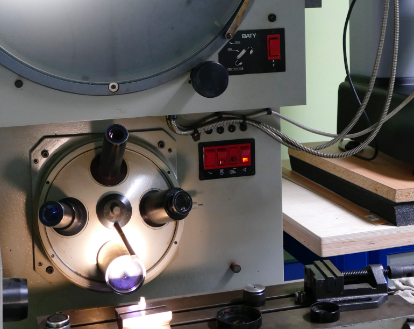

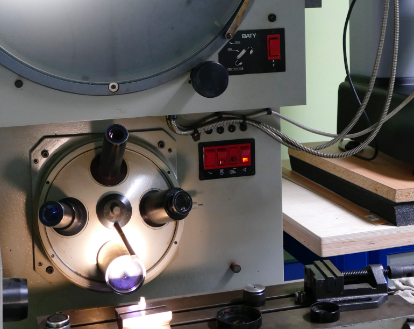

OPTICAL MEASURING TESTER

Find out moreTEST DESCRIPTION: The tester examines the linear dimensions, i.e. diameter of the thread, core, head, insertion, lengths and heights, and dimensions of angles. The encoder integrated in the screen allows for quick angle measurements with an accuracy of up to 1 minute. The Quadrachek 200 electronics, in addition to reading the position in the X and Y axes, also enables figure measurements (point, line, circle, radius, angle), construction of a coordinate system on a component, input of tolerances and determination of relationships between measured figures. The device is used to make very accurate measurements with an accuracy of 0.001 mm. It enables measurements to be taken and samples to be viewed at up to 50x magnification.

MEASURING DEVICE FOR TESTING THE DRILLING SPEED DELTA

Find out moreIt is used to study the drilling time of self-drilling screws. Examines drilling time in various materials with well-defined properties. The tested products are mainly: self-drilling screws, screws for window and door joinery and roof coverings. TESTING ACCORDING TO ISO 10666.

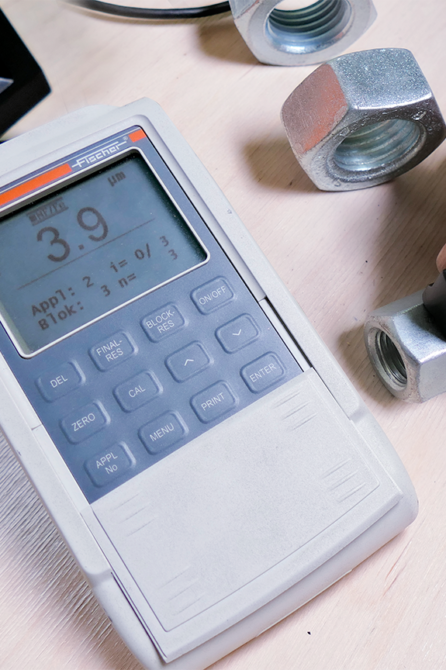

Delta Scope Fischer

Find out morePRZEZNACZENIE: przenośne urządzenie do badania powłoki (do stosowania w terenie, ale o dokładności). Minimalne słup powierzchni badanej powinno być płaskie i większe 4mm2. Aby rozwiązanie stosowane jest do kontroli jakości losowych i całych serii podczas bieżącej produkcji i przy odbiorze towarów.

OPIS BADANIA: szybki i nieniszczący zanurzanie zanurzania na podłożach ze stali (F) i metali nieżelaznych (NF).

JESZCZE WIĘKSZA PRECYZJA POMIARÓW DZIĘKI: możliwości wyników pomiarów wg IMO PSPC, SSPC-PA2, QUALANOD i QUALICOAT. Ponad 70 głosów precyzyjnych.

SALT SPRAY TEST CHAMBER

Find out moreIt is used in the resistance class and susceptibility of materials and conditions to unfavorable conditions causing corrosion corrosion. The salt chamber used by Marcopol is a class device that allows even a 100-fold acceleration of corrosion processes. Destructive and long-term test (from 6 to 2644 hours – depending on the coating).

PURPOSE: it is used to test the corrosion resistance of elements covered with various coatings.

TEST DESCRIPTION: the test consists in placing the test samples in a chamber saturated with NaCl salt solution with a concentration of 5% and temperature of 35 ° C (neutral salt spray) and waiting for the appearance of: white rust (coating corrosion) or red rust (steel corrosion). After the end of the test, the appearance, weight loss, number and distribution of corrosion defects. TEST ACCORDING TO THE PN-EN ISO 9227: 2012E STANDARD

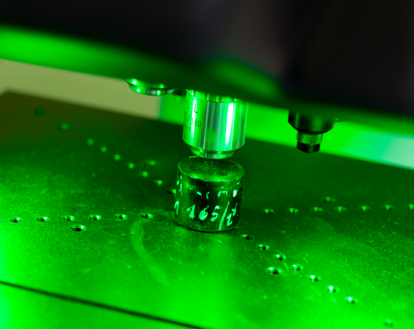

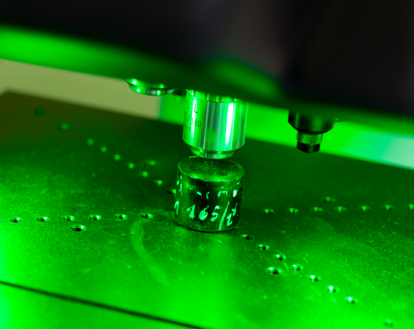

FISHERSCOPE X-RAY X-ray fluorescence spectrometer

Find out moreThe modern X-ray fluorescence spectrometer is designed for manual or automatic measurement of coating thickness and material analysis. The device enables coating thickness measurements up to 80μm, with a measuring surface of Ø 0.25 mm and a repeatability of 2.5 nm with a measuring time of 20 seconds. It is used to test the resistance and susceptibility of materials and coatings to unfavorable weather conditions causing corrosion. The salt chamber used by Marcopol is a top-class device that allows up to 100 times acceleration of corrosion processes. Destructive and long-term test (from 6 to 2644 hours – depending on the coating).

PURPOSE: allows you to check the actual thickness of the coating in relation to the one declared by the supplier. Thickness measurement of coatings such as Au / Ni, Au / PdNi / Ni, Ag / Ni or Sn / Ni or Sn / Cu / PCB. Anti-corrosion coating thickness measurement. Coating measurement at joints. Determination of the metal content in electroplating baths. Automated measurements of large batches of samples possible.

TEST DESCRIPTION: the radiation beam attacks the measuring surface from above, being able to spot spot the coating thickness in different places of one element (head, core). Thanks to the possibility of adjusting the voltage and the filter, it enables the measurement of thin and thick coatings (e.g. 50 nm or 100 μm Sn). The proportional counter provides a high count threshold, reaching several kcps. The use of the measuring path from the bottom to the top allows for quick and easy positioning of the sample. The X-ray tube placed at the bottom of the detector makes it easy to position the sample directly on the measurement window. The micro-focus X-ray tube enables precise measurements on small details. TEST ACCORDING TO DIN 50987 and ISO 3497.