- Home page

- Marcopol LAB

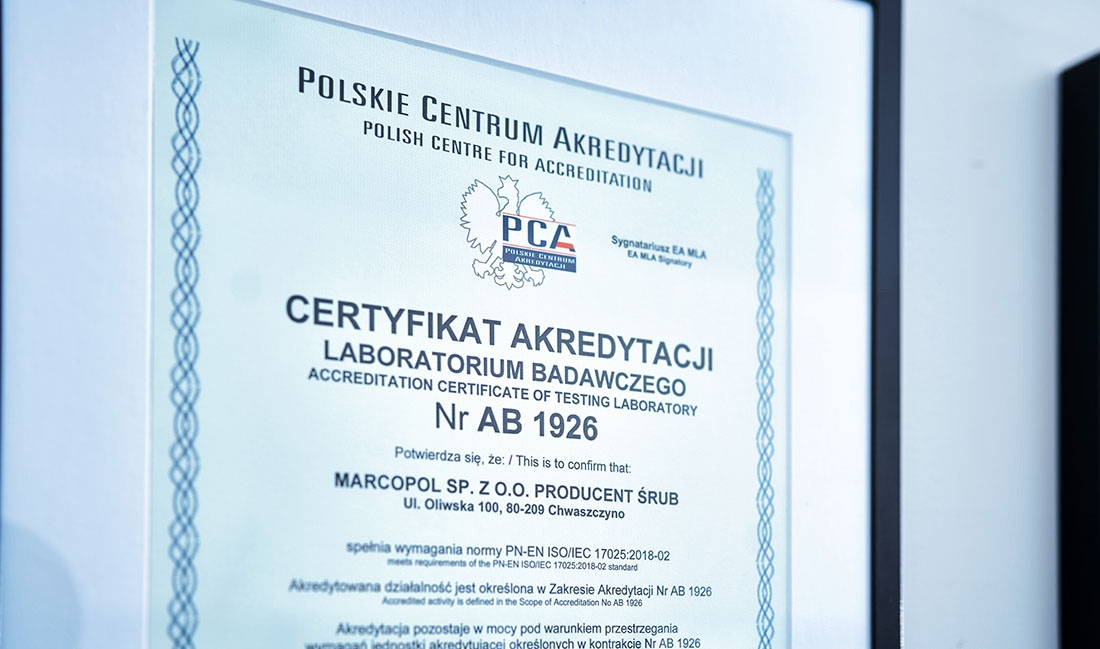

Professional testing facilities confirmed by PCA accreditation.

The Marcopol quality testing laboratory has been accredited by the Polish Centre for Accreditation (PCA) with confirmed compliance with ISO/IEC 17025:2017 – the most important international standard defining the competences of testing and calibration laboratories.

This formally confirms that our testing processes are independent, reproducible, and fully reliable.

What do you gain by choosing MarcopolLAB?

Results Accepted Everywhere in EU

Test reports bearing the PCA mark are accepted by public institutions and industrial partners in Poland and the European Union.

Reliable Confirmation of Product Quality

Each test document constitutes official proof of product compliance with technical specifications and supports supplier approval processes and quality audits.

Experienced Team of Experts

Our staff has undergone comprehensive training and possesses certified competencies – we follow the highest industry standards.

Impartiality and Compliance with Regulatory Requirements

We operate as an independent testing facility – our results are objective and can be used in technical documentation and compliance reports.

Accredited test methods at MarcopolLAB

Our laboratory is accredited for the following test methods:

Inductively coupled plasma – optical emission spectroscopy (ICP-OES)

- Determination of the content of the following elements: carbon, chromium, manganese, molybdenum, nickel, phosphorus, and sulphur in steel products

Vickers hardness test

- HV hardness measurement in the following range: HV 0,3; HV 5; HV 10

Energy-dispersive X-ray fluorescence method (ED-XRF)

- Zn/Fe coating thickness testing in the range of (1.4 – 35.0) μm

Additional tests performed at MarcopolLAB

In addition to accredited methods, we also offer:

- Salt spray corrosion test

- Durability assessment of anti-corrosion coatings in accordance with relevant ISO standards

- Static tensile test

- Analysis of mechanical properties of materials using a tensile testing machine

- Rockwell hardness test

“Falcon” Vickers Hardness Tester

This advanced device measures hardness and hardened layer thickness. It allows for the analysis of CHD, Nht, and Rht parameters, as well as the assessment of microstructural changes. Nht, Rht oraz ocenę zmian mikrostrukturalnych.

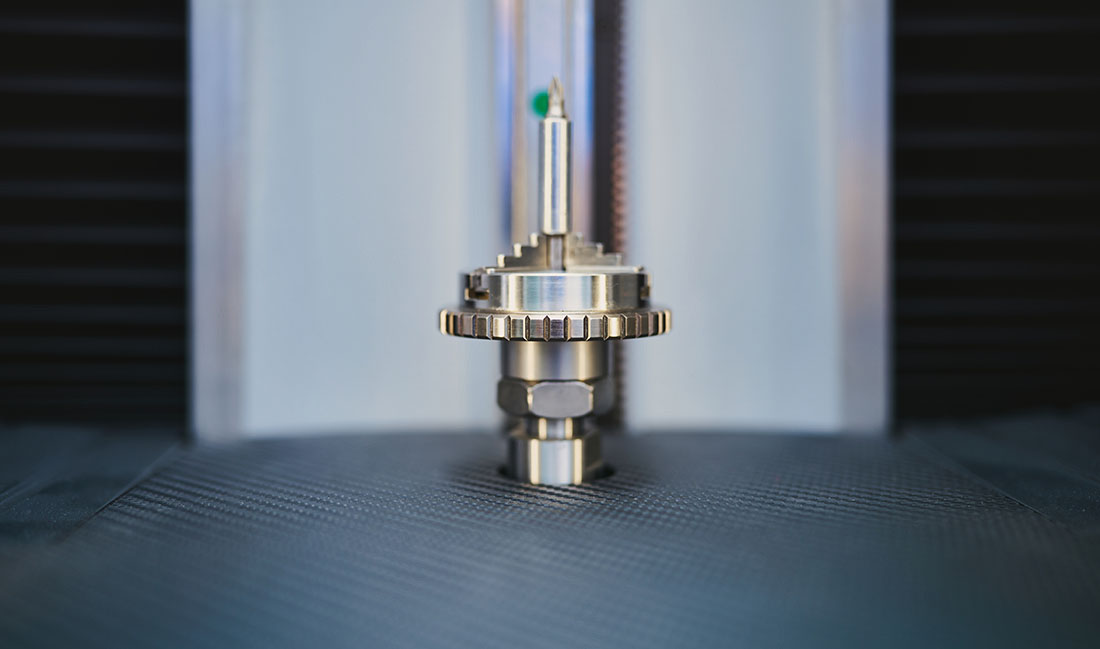

XRF X-Ray Fluorescence Spectrometer

A modern device designed for performing analysis of coating thickness and metal composition without sample destruction. It enables measurements with nanometer accuracy, in accordance with ISO 3497 and DIN 50987 standards.

OES Spark Optical Emission Spectrometer (Hitachi Foundry-Master Smart)

An advanced device for fast determination of the chemical composition of metals and their alloys. Thanks to the integrated GRADE Database, it allows for rapid matching of material grades to applicable standards.

Tensile Testing Machine

This machine is used to test the breaking strength of metal components and verify their mechanical properties. A range of up to 500 kN allows for testing even the most durable samples.

Salt Spray Chamber

The chamber simulates accelerated atmospheric conditions to assess the corrosion resistance of coatings. Tests can last from 6 to over 2,600 hours and are compliant with the PN-EN ISO 9227 standard.

VICI VISION – Optical Dimension Measurement System

An optical measuring machine for non-contact dimensional inspection. It enables rapid measurement of diameters, lengths, threads, and radii in a single cycle, with micrometer accuracy.

Rockwell Hardness Tester

The Rockwell hardness tester is used to quickly and reproducibly measure the hardness of metals on the HRA/HRB/HRC scale.

Eclipse LV150N Metallographic Microscope

A professional microscope for checking material structure, analyzing coatings, and identifying damage to connecting elements. It supports advanced optical techniques (DIC, dark field, epifluorescence) and NIS-Elements software for measurement and documentation.

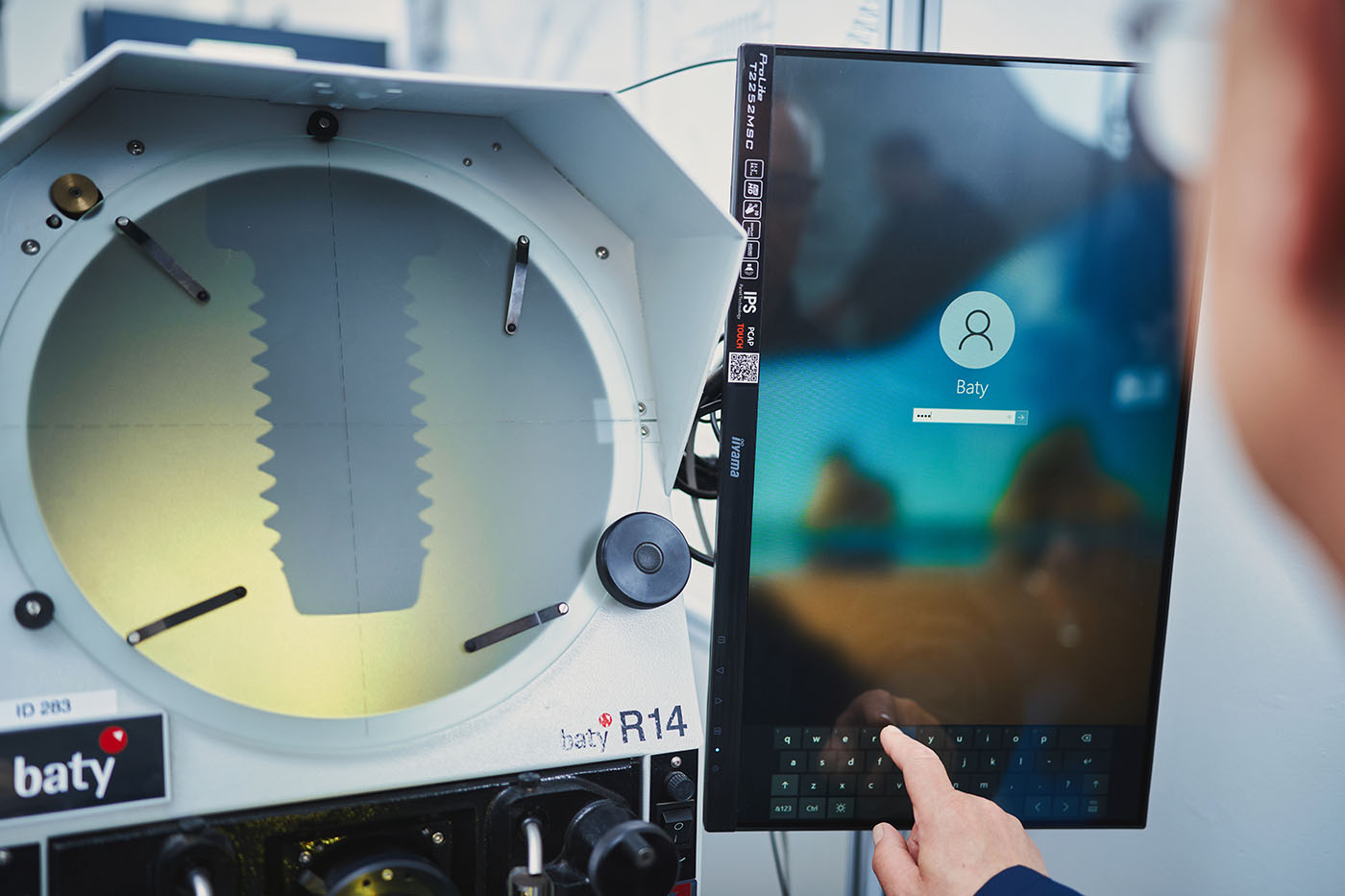

Optical Profile Projector

A non-contact device for measuring linear dimensions and angles with an accuracy of 0.001 mm. Ideal for analyzing the geometry of screws, threads, and precision components.

Automatic Optical Sorter - TYPE 1

A high-precision machine for sorting small screws and bolts up to 25 mm long. The sorter guarantees precise quality control with a throughput of 400 pieces per minute.

Automatic Optical Sorter - TYPE 2

A versatile device for inspecting medium-sized connecting elements up to 110 mm long. It can sort at speeds of up to 900 pieces per minute while maintaining complete measurement repeatability.

Automatic Optical Sorter - TYPE 3

A specialized machine for testing longer threaded components—up to 150 mm in length. It enables precise assessment of thread straightness, length, and geometry.

Drill Speed Testing Machine

Measures the time it takes for self-drilling screws to drill through sheet metal. The test is performed in accordance with the ISO 10666 standard and is used in assembly quality tests.

Experienced Team of Experts

Our laboratory’s high-quality and reliable testing is ensured by experienced specialists whose knowledge and commitment guarantee reliable results.

This team combines practical experience with in-depth knowledge of technical standards and quality requirements applicable in various industries.

Jagoda Kruza

Quality Manager

Marcin Brzozowski

Quality Engineer

Katarzyna Morawka

Quality Specialist

Piotr Drabiński

Quality Specialist

Meet MarcopolLAB – our accredited testing laboratory

Looking for a reliable partner for materials testing?

Fill out the contact form and our specialist will contact you within 24 hours.